S14

NICOLAI’S BEST TRAILBIKE EVER...

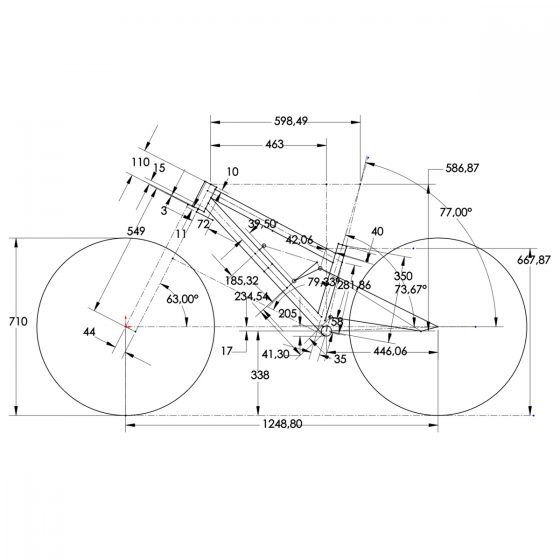

NICOLAI’s interpretation of the radical trail bike is the S14. With its modern and balanced GEOLUTION TRAIL geometry it’s perfect for a lap from home, around a trail centre, or a 5-day XC race. Agile, stable and easy-climbing, that’s what GEOLUTION TRAIL brings to the party. You can say goodbye to going ‘over the bars’ and the front wheel ‘wandering’ uphill. Just get on with riding! With two possible wheel sizes, geometry adjustment and water bottle mounts, it is the most versatile NICOLAI trail bike we have ever built.

REINFORCED TUBESET + GUSSETS

NOW EVEN MORE STABLE WITH THE ST UPGRADE

We offer the S14 in two versions. The S14 with the suffix ST (SUPER TRAIL) is manufactured with a reinforced tube set. This gives the bike clearance for forks with an length of up to 570mm and a diameter of 36mm. The standard S14 has no approval for the bike park and the fork length is limited to 550mm. The frame weight increases by about 300gr depending on the frame size.

#GEOLUTION trail

MORE SPEED, MORE FUN

The roots of the Geolution concept lie in enduro racing, and even if trends in frame geometries are slowly approaching a similar concept, Geolution can still be seen as a radical design in which performance is top priority. But not all of our customers also put the emphasis here or strive for the top steps at enduro races. They are more interested in a well-rounded bike that can climb well, master any trail and has strong downhill potential.

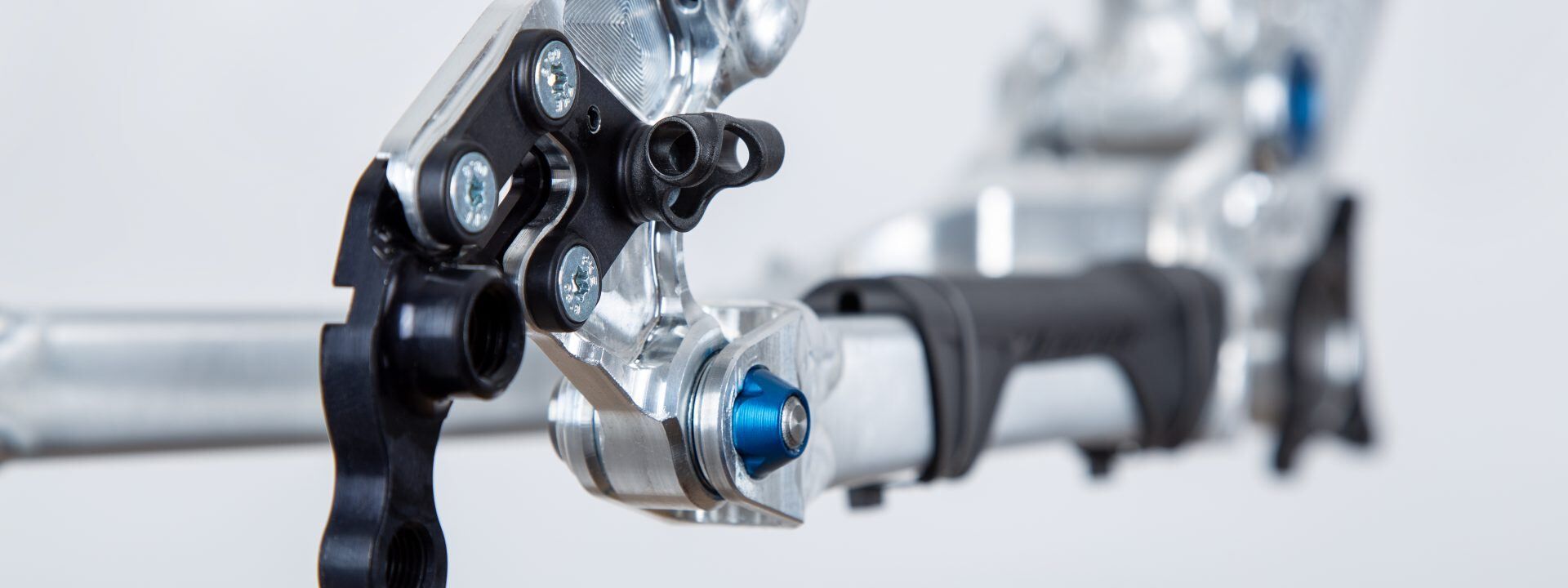

PRESSURE STRUT MUTATOR

ONE FRAME, TWO WHEEL SIZES

27.5”, 29”, or both ? Thanks to the Mutator chips located on the seat stay and lower headset cups to change the stack height, one S14 frame can be configured anyway you choose. Big wheels for big riders, small wheels for smaller riders, hybrid sizes for those who want the best of both worlds.

WELDING TECHNOLOGY

A NICOLAI IS ALWAYS RECOGNIZABLE BY ITS WELDS.

We weld all of our frames by hand using the TIG (Tungsten Inert Gas) method. Our specially trained welders have many years of experience, our lead welder has worked in-house for over 20 years. For each model and frame size we build a precise welding structure called the frame jig. In this jig, the CNC-cut tube sets are precisely assembled and fixed in place with all turned and milled parts of the frame to be welded. The frame components are first tacked together with individual spot welds at precise points in a defined sequence, and then, to minimize distortion and stresses, welded in several passes.

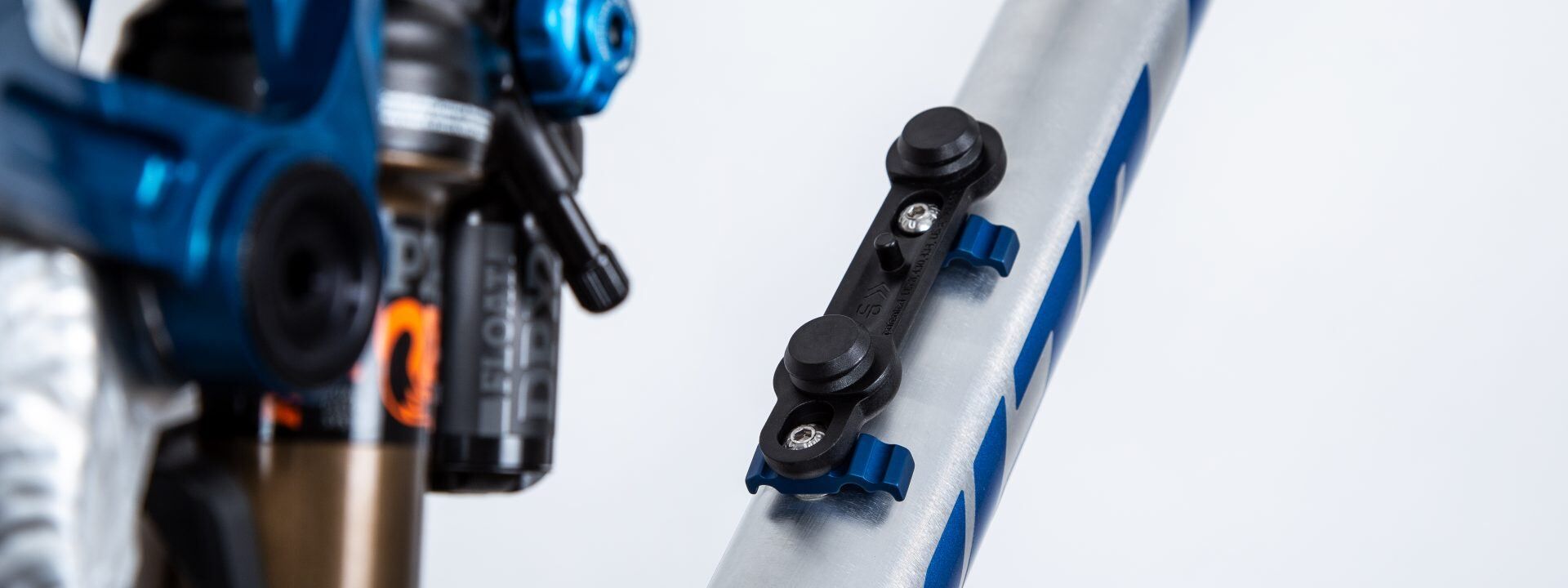

BOTTLE CAGE

Attachment points for water bottles and accessories

Even though many riders now rely on hydration or hip packs, few want to do without the option of a bottle cage within the front triangle. For a clean look, we offer our customised magnetic FIDLOCK mount together with a NICOLAI 0.6L Twist bottle. The FIDLOCK mount allows intuitive release and engagement of the water bottle in both directions even while riding, plus it’s secured in the frame even on the wildest rides and hardest hits. For further mounting options, for example to attach small toolboxes, pumps or bags, the NICOLAI frame clamps from our accessories line are ideal.

Topology Optimization

When designing turned and CNC milled parts, we use FEM software (Finite Element Method), which can be used to simulate the loads that will occur on the trail in order to determine the optimum shape (topology) of these components. Critical areas of the design become visible in this way and can be strengthened by adding material, or weight can be saved by removing material from low stress areas. In this way we can produce highly complex parts and assemblies for our frames that combine maximum durability with minimum weight.

7020-T6 Aluminium

ALUMINIUM IS NOT ALUMINIUM

We at NICOLAI exclusively use the alloy 7020-T6 (AlZn4,5Mg1) for our frames. Compared to our competitors, who mostly use aluminium 6061-T6, this grade has much better strength values.

ANGULAR CONTACT BEARINGS

4 WAY SEALED

The rear triangle of a full suspension bike is not a statically rigid component and is exposed to extreme loads during driving. Critical points are the ball bearings, which ensure low breakaway torque and optimum response of the chassis. In order to extend the maintenance intervals of the frame, Nicolai products rely exclusively on full complement, double-sealed ball bearings.

Rado

Rear Aligning Dropout

So that you can hit every lane on the trail, we mount a form-fit sliding, exchangeable dropout for track and camber adjustment on all frames. Due to the differently milled, right dropouts for adjusting the lintel, the rear only needs to be slightly readjusted after installation. This takes the strain off the material. The respective lintel height is milled into the RADO with the digits 0, 1, 2 or -1 and -2. After the toe and camber have been set, the RADO is fixed ex works with a pin. This makes the original setting easily reproducible during replacement. This is the only way we can guarantee that NICOLAI products work precisely on the track.

MANUFACTURING QUALITY

Made in Germany

The manufacturing quality itself is not yet an added value for a customer. The following two added values “durability & precise driving characteristics”result from production quality. Only if the welds are welded deep into the root and have no notches, a bike frame can withstand the impacts from the ground for many years without breaking. Precise riding characteristics are achieved when the rear wheel is precisely straight to the front wheel and even a layman notices that an oblique bike rides strangely (but usually he thinks it’s because of his riding ability).

Extra Love

POWDER AND ANODIZED COLORS, DECORS, CUSTOMIZING, INDIVIDUALIZATION

TAILOR MADE

OPTIONAL DIMENSIONAL FRAME CONSTRUCTION AND CUSTOMIZATION

WARRANTY AND SPARE PARTS

BIKE CONFIGURATOR

Like all Nicolai bikes, customisation is key. Choose from a frame only at €2,499 or complete builds starting from €6,499 with only the best parts from FOX, INTEND, HOPE, MAGURA, TUNE, CONTINENTAL, SRAM and LEVELNINE.

TRADE AND DISTRIBUTION

NICOLAI frame kits and complete bikes are offered in Germany through our direct sales channel. We offer off the shelf models, or completely customized dream builds with a wide choice of components via our online configurator. Personal discussions and direct contact with customers are our top priority. Abroad, selected partners are available for sales. With our large test bike fleet, we regularly visit bike parks and trail centers around central Europe. Here, potential NICOLAI riders can extensively test our bikes after prior registration and receive individual advice. At the NICOLAI factory we have set up a showroom where all current models are on display. Here, you can also make appointments for personal consultations, test rides, buy bikes directly or pick up pre-ordered bikes.