THAT`S US - NICOLAI BICYCLES

WHY WE LOVE WHAT WE DO

REAL NICOLAI

THE PROCESS

DEVELOPMENT

Each NICOLAI frame is developed in Mehle. The complete production process of constructing, building prototypes and testing takes place here. While developing, we use the feedback of our team riders and customers as well as our own experiences as active bikers. Our goal is simply defined: Best function, best resistance and the best reliability to make good bikes even better.

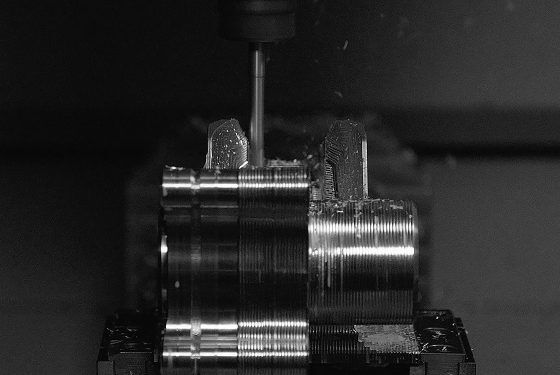

MILLING

WELDING

STRAIGHTENING

COATING

PREPARATION FOR ASSEMBLY

THE TEAM

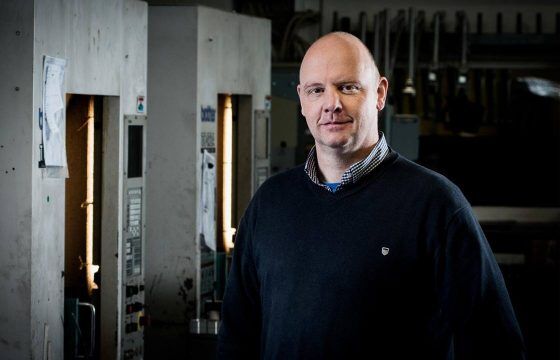

Kalle Nicolai

CEO

BENJAMIN BÖRRIES

Geschäftsführer

Vincent Stoyhe

Head of Sales

Niko Grobe

Creative Director

Benedikt Blome

Einkauf / Produktionsplanung

Philipp Sander

Ingenieur / Massrahmen

Hendrik Schlünß

Sales

SARAH JAHNEL

Sales

FELIX LÜKE

Sales Trainee

ANNA GEFFERT

Sales

FRANZ HECKMANN

Sales

Volker Johst

After Sales / Service

Patrizia Musil

Sales NC1 - Assistentin der Geschäftsleitung

FLORIN RÄTHEL-WOLF

Sales B2B

Claus Papendorf

Montageleitung / Service & After Sales

Jens Miller

Ingenieur / Massrahmen

Markus Schmidt

Betriebsleiter

Fabian Mende

Konstruktion / Entwicklung

DALIBOR KOS

Ingenieur

Stefan Wickenhäuser

CNC-Produktion / Leiter Betriebstechnik

Jens Kienlin

Pulverbeschichter und Monteur

BENEDIKT REICHARDT

Konstruktion / Entwicklung

Constatin Stach

Montage

Sascha Kanne

Schweisser

Torsten Knoke

Schweisser

CASJEN FRIEDRICH JOHANN JESCHKE

CNC Produktion

HANNES HAGEN

CNC Produktion

Daniel Trantow

CNC-Rohrzuschnitt

Christian Suhrly

CNC-Produktion

Regina Kostka

CNC-Produktion

Jan-Hendrik Kunz

Lagerverwaltung Rahmenbauteile

Marcel Rotermundt

Zerspanungsmechaniker

Chris Thomas

Pulverbeschichter

Felix Schuster

CNC Produktion

MORITZ KÄHLIG

CNC Produktion

Philipp KoitscH

Projekt Manager

Danilo Stahn

Betriebstechnik

Yannick BADE

Cargo Montage

Walter Hebbel

The Transporter / Versand

Birgit Kusch

CNC-Produktion