ARGON GX SWIFT

Efficiency + speed with high comfort and off-road potential

The Argon GX SWIFT is a gravel e-bike that is based on our regular Argon GX and is available in two high-quality builds fitted with the new Bosch Performance Line SX drive. Remote back roads, gravel tracks, fire roads, forest paths or single trails: the Argon GX SWIFT feels right at home on these terrains as the fastest, most efficient and most enjoyable way to get around. It offers the best of both worlds: the efficiency and speed of a road bike combined with greater comfort - as well as the off-road capability and stability of an XC bike. The Argon GX SWIFT is available as a 7.0 and 8.0 version and as a frame kit. On top of this, we always offer you the option of having your bike fitted with your personal dream components as a custom build.

Version 8.0

High-Calibre equipment for maximum performance and reliability

The 8.0 is the top model in the Argon GX SWIFT series and comes with top-class equipment for maximum performance and reliability. It stands out from the 7.0 in particular when it comes to shifting. The 8.0 uses the electronically controlled, wireless SRAM Force AXS 1x12. The carbon fork and stem from Moquai are perfectly matched and integrate the cables for a clean look. Just like the stem length of 70 - 90 mm, the width of the Easton EA50 AX handlebars varies from 40 to 44 cm, depending on the frame size.

System integration

Technical integration of the Bosch drive in all details

As a Bosch partner, we have been working closely with the world's leading developer of e-bike drives for many years and are very familiar with their technology. That's why we don't talk about installing the BOSCH drive, but about integration. This means taking into account a wide range of technical aspects concerning the drive itself, its secondary characteristics as well as the entire periphery.

Bosch Power

Performance Line SX motor - lightweight and compact

The Bosch Performance Line SX motor provides the basis for the Argon SWIFT models. With a total weight of only 2.05kg, it’s 1kg lighter compared to the widely used Bosch Performance Line CX motor. It also establishes a new mounting standard that allows a lighter frame construction. In combination with the new internal Compact Tube 400Wh battery, which weighs a mere 2.0kg, the result is an unprecedented system weight of only 4.05kg.

Bosch Power Tube 400 Akku and Range Extender

Maximum Power density at minimum weight

The Argon SWIFT models are fitted with the Bosch Power Tube 400 battery as standard, with a capacity of 400Wh and only 2kg. For more miles, the Bosch Range Extender can be used, a compact 250Wh auxiliary battery attached to the downtube's bottle cage mount, where it has sufficient clearance on all frame sizes. This mount complies with the new Bosch standard, which allows either a bottle cage or the special mount for the Bosch Range Extender to be locked in place without tools. The Argon GX SWIFT also has two additional bottle cage mounts, one on the seat tube and one under the top tube. Sufficient hydration is therefore ensured even for long distances.

Bosch System Controller & Mini Remote

Always in view and within reach

Discreetly and well protected, the new Bosch System Controller control unit is integrated into the top tube of the Argon GX SWIFT. With a compact design, it has just two push buttons for switching the bike on and off and for selecting the assist mode. Bright, colored LEDs indicate the state of charge in 10% steps and the selected mode. To keep your hands on the handlebars at all times, all key functions can be accessed from there via the Mini Remote control unit. The System Controller also acts as a Bluetooth interface for the eBike Flow app on the smartphone. This allows riding data to be logged and software updates to be installed. Smart functions such as eBike Lock for theft protection can also be used with the System Controller.

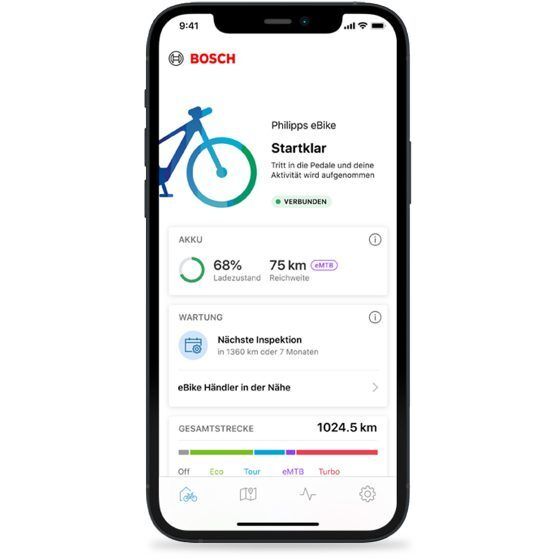

BOSCH eBike Flow App

Setup and connectivity

Discreetly and well protected, the new Bosch System Controller control unit is integrated into the top tube of the Argon GX SWIFT. With a compact design, it has just two push buttons for switching the bike on and off and for selecting the assist mode. Bright, colored LEDs indicate the state of charge in 10% steps and the selected mode. To keep your hands on the handlebars at all times, all key functions can be accessed from there via the Mini Remote control unit. The System Controller also acts as a Bluetooth interface for the eBike Flow app on the smartphone. This allows riding data to be logged and software updates to be installed. Smart functions such as eBike Lock for theft protection can also be used with the System Controller.

Explorer Kit

Trekking, Packing, Commuting

If you want to expand the range of use of your Argon GX SWIFT, for example, to use it for commuting, as a travel bike or daily ride, you are perfectly suited with our Explorer Kit, which is available as an option. The Explorer Kit consists of robust mudguards, a strong rack and powerful, road-legal lights. This makes your Argon GX SWIFT ready to go for everyday riding and for adventures alike. The high-quality components of the kit are chosen to work perfectly together, ensuring an optimal fit and compatibility with the bike. The Explorer Kit will be installed ready-to-ride with your bike order.

Topology optimisation

Computer-aided design to optimize durability, function and weight

When designing turned and milled parts, we use FEM software (Finite Element Method), which allows us to simulate the loads that will occur in later use in order to determine the optimum shape (topology) of these components. Critical structural areas become visible this way and can be strengthened by adding material, whereas material can be saved at less stressed areas. This way we can produce highly complex parts and assemblies for our frames that combine maximum durability with minimum weight.

HMT - Hollow Milled Technology

Load and weight-optimized, hollow milled volumetric components

Hollow Milled technology is a design and manufacturing process that allows for maximum material and weight savings in the CNC production of highly stressed volume components such as the seat and chainstay yokes of our new Argon generation without weakening the construction. For this purpose, the stress zones in the material are determined by computer simulation during the design phase. Highly stressed areas can thus be reinforced, while material can be saved in less stressed areas. This method is called topology optimization. Thanks to the deployment of state-of-the-art 5-axis milling machines, we are able to manufacture highly complex, hollow milled frame components from a single piece and transfer the optimized design with the highest level of detail. The new Argon yokes are therefore not only light and durable, they also look damn good.

5 frame sizes

Adaptive geometry and load-dependent modification

For this frame we offer 5 sizes from S to XXL, suitable for body heights of 1.60 and 2.10 meters. A chart of body and frame sizes can be found in the Tech Sheets attachment to this model. Building a perfectly fitting frame means more than just scaling its initial shape. Here we take into account various factors in terms of body proportions and rider weights, for example adapted tube cross-sections, modified riding angles and low standover heights for S-sizes as well as frame reinforcements that take into account the heavier weight and greater body strength of XXL riders. For fine-tuning the geometry, saddle position, stem height, or handlebar width and angle can be adjusted.

Powder coating and anodizing

Extralove

In addition to the basic configuration, in which we offer the frame without color in brushed aluminum look as Factory Raw with black anodized, mounted milled parts, there is the option of individual color choice. With our in-house powder coating facility, you have 27 colors to choose from, each of which can be applied in a high-gloss or semi-gloss finish.

7020 Aluminum

Sustainable and durable, the stuff of dreams

All NICOLAI frames are made of 7020-T6 aircraft aluminum and we are convinced that this alloy is the superior material for the construction of mountain bikes. Compared to the 6061-T6 (AlMg1SiCu) alloy normally used in bicycle construction, 7020-T6 (AlZn4.5Mg1) has about 30% higher tensile strength and about 20% higher elastic limit. And where carbon frames can spontaneously break and collapse in the event of an overload, NICOLAI bikes are calculated and designed to deform in a defined area of the frame in the event of an overload, significantly reducing the risk of serious crashes and injuries. A NICOLAI aluminum frame is designed to withstand many years even under tough competition conditions.

NICOLAI welding

Craftsmanship and engineering at its best

We weld our frames manually using the TIG process. Our welders are specially trained and with many years of experience. For each model and frame size, a precise welding fixture is built, called a frame gauge. Here, the CNC-cut tube sets with all turned and milled parts of a frame that are to be welded are precisely put together and fastened. The frame parts are first tack-welded at exactly specified points and in a defined sequence and then, in order to minimize distortion and stresses, welded in several runs.

Warranty and spare parts supply

We provide a 5-year warranty on all frame models against breakage and material failure, even in racing use or when jumping. The prerequisite is that the respective models are used within the scope of their designated purpose and have been equipped only with the components for which there is an approval. In addition, we guarantee a spare parts supply for all models over a period of at least 10 years. Since we manufacture all parts of our frames in-house and on our own machines, it is even possible to reproduce spare parts beyond the 10-year period in some cases.

BIKEBOX

We have developed an elaborate reusable bike box for our mail-order shipping. In it, the new NICOLAI bike arrives protected in a wooden frame and guaranteed safe at the customer and is ready for use after a few simple steps. The same box is reused when the bike is returned to us for repair or service. All shipping protections of the bike box such as pads, lashing straps, brackets and screw connections are also reusable.

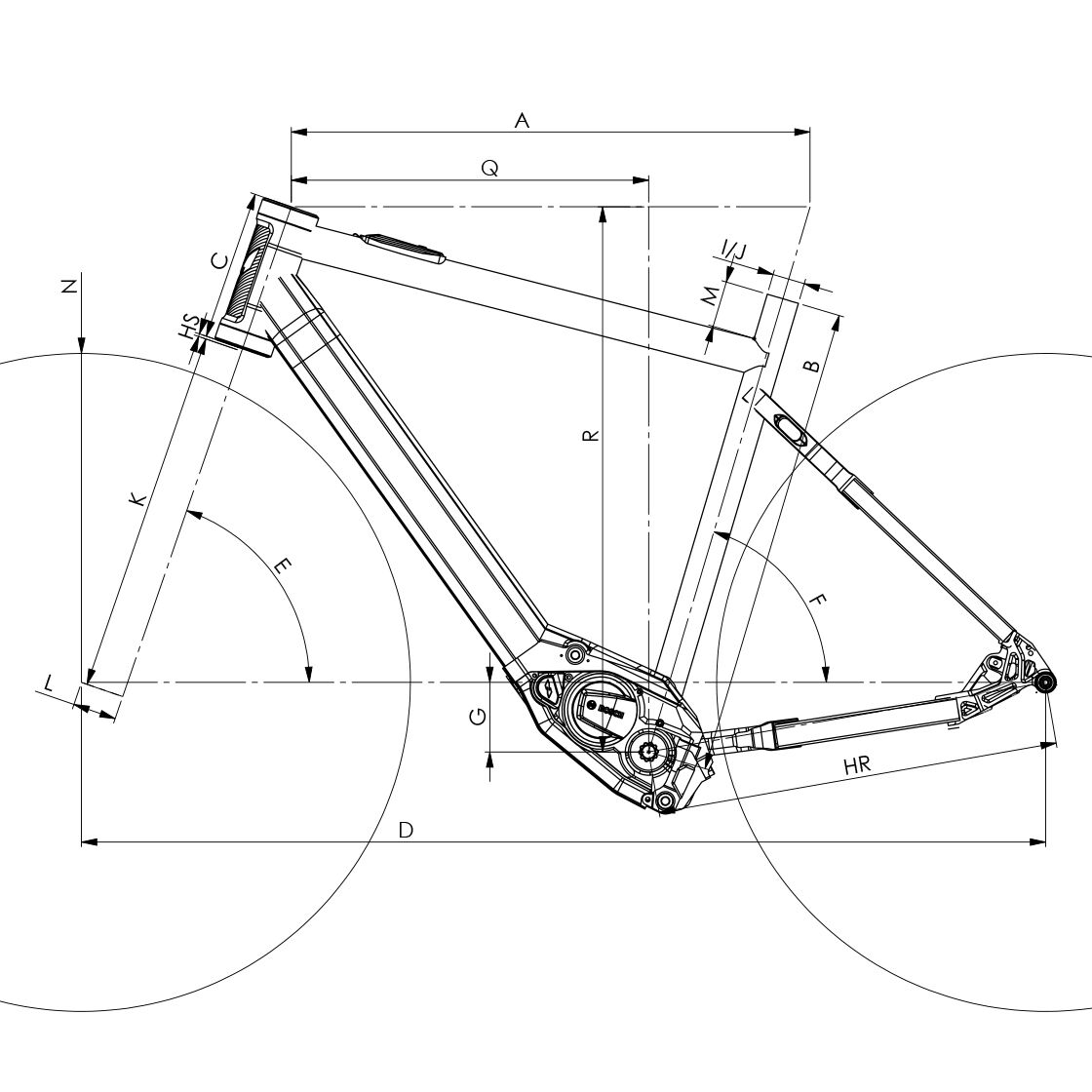

Geometry

Suitable for riders from 160 cm to 208 cm

The Argon GX SWIFT largely adopts the proven, balanced geometry of our regular Argon GX gravel bike. A relatively long top tube and reach ensure sportiness, efficiency and speed. The height of the front, the stack, has been optimized for comfort to ensure long, fatigue-free riding and maximum bike control off-road. A slack steering angle and a longer rear end increase smoothness and riding stability on unpaved paths and trails. We have designed the Argon GX SWIFT with an adaptive geometry that takes into account weight and proportion factors for different body sizes. As the length and height of the main frame increases, the seat angle becomes slacker for larger frames, while the steering angle becomes steeper. This ensures that the character of the bike remains the same in every size. The Argon GX is available in 6 frame sizes, from XS to XXL, suitable for riders from 160 cm to 208 cm.