G1 EBOXX KLF

competitive, ambitious, efficient

The G1 EBOXX KLF is the most aggressive, lightest and fastest bike in the EBOXX line-up. Thanks to its long, flat Geolution design, it masters even the toughest enduro tracks with breathtaking speed. With its SRAM GX Eagle derailleur, this bike has the most efficient drivetrain of all EBOXX models, getting the most out of the Bosch Performance Line CX drive. Optionally, the CX Race motor is also available here. Featuring the superior EXT suspension, it has all you need for a professional race setup. The G1 EBOXX KLF is the perfect bike for you if pure performance is your top priority, whether it's on technical single trails, in the bike park or for E-Enduro racing.

Geolution

the exclusive enduro competition geometry

Geolution is a unique geometry concept based on the idea that a longer wheelbase, flatter steering angle and steeper seat angle make the bike faster, smoother, easier to climb and also safer. Climbing performance is improved because the steep seat angle and long front end put the rider in a position that prevents the front wheel from rising on steep climbs.

Suspension and kinematics

Alongside the geometry, the suspension of a mountain bike, in particular the design of the suspended rear end, is a decisive factor for riding fun and performance. We want to combine with our EBOXX models a competitive performance and maximum fun on the trail with a high efficiency when pedaling and therefore build our rear ends based on the Horst-Link design. Horst-Link is the name given to the pivot that is located at the end of the chainstay in front of the rear axle and counteracts the shortening of the wheelbase during compression.

BOSCH Performance Line CX or RACE

YOU HAVE THE CHOICE

The Bosch Performance Line CX is a powerful, reliable drive unit with a peak power of 600 W and an assist of up to 340%. Its maximum torque of 85 Nm ensures great acceleration even at low cadence, for example after tight turns or when getting started on a climb. For fast sprints, however, the motor also supports at high cadence. Its dynamic power output ensures intuitive handling and a unique riding experience. In adaptive eMTB mode, technical sections can be confidently ridden through and obstacles such as steps, rocks or thick roots can be easily overcome by one controlled pedal push with the help of the Extended Boost feature.

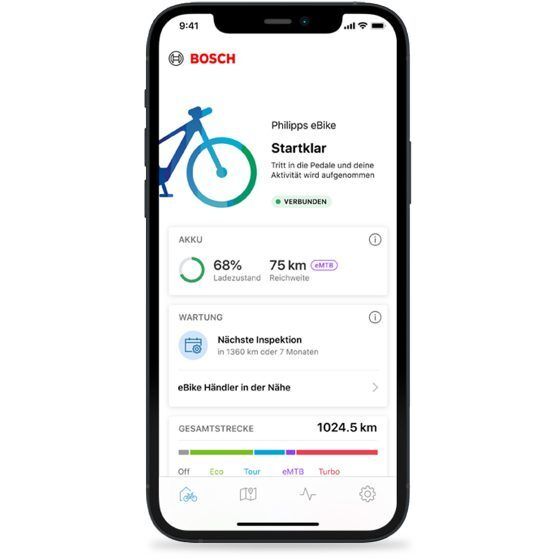

Smart System and eBike Flow App

Always informed and oriented

The motor unit is interconnected with the other system components such as the battery, display and control unit via the Bosch Smart System. Using the eBike Flow app on the smartphone, the riding modes can be configured and adapted to personal preferences and requirements. Likewise, functions such as navigation or theft protection can be used via the eBike Flow app. System updates and extensions can be downloaded via the app and easily installed to the Smart System via Bluetooth. With the eBike Flow app and the Smart System, the EBOXX always remains up to date and can be continuously upgraded with new functions.

BOSCH Kiox 300 Display

A display for sporty eBikers

The BOSCH Kiox on-board computer serves as the EBOXX models' control center. The scratch-resistant, large color display is perfectly readable in all lighting conditions thanks to its adaptive brightness control. In addition to standard functions such as assist mode, speed, and state of charge, distance and range are also displayed. Other functions of the BOSCH Kiox are aimed particularly at sports riders: The rider's power in watts can be displayed, as well as heart rate when a cardio belt is used. The control of functions such as riding mode selection or changing menu items is done via the LED Remote at the left handlebar grip. The EBOXX can also be used without the Kiox 300 displays solely using the LED Remote, which purists and hardcore enduro fans in particular will appreciate.

BOSCH LED-Remote

Control without display

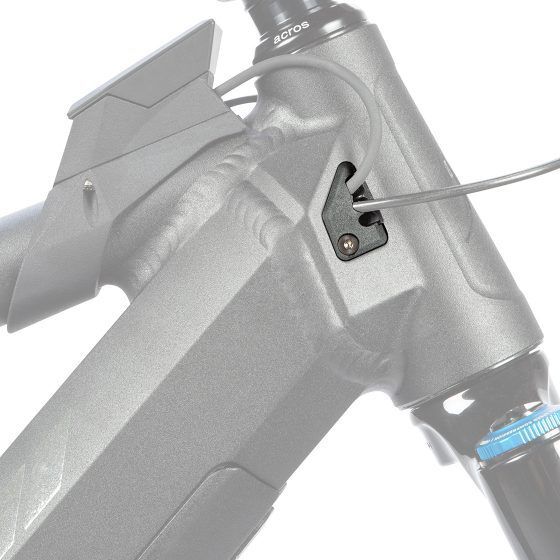

The Bosch LED Remote enables you to intuitively operate the EBOXX bike and provides both haptic feedback through the click-stops of its buttons and visual feedback through bright, easy-to-read LED light bars that indicate the selected riding mode as well as the state of charge of the battery. The luminosity automatically adjusts to the ambient light. The optimized ergonomics of the control unit ensure easy and safe handling.

System connectivity

As a BOSCH partner, we have been working closely with the world's leading developer of e-bike drives for many years and are very familiar with their technology. That's why we don't talk about installing the BOSCH drive, but about integration. This means taking into account a wide range of technical aspects regarding the drive itself, its secondary properties, and the entire periphery.

suspension

EXT

To get the maximum potential from a suspension system, after the frame design, the choice of the right suspension components is crucial. On all models, we use modified custom shocks as needed, whose shim stacks ( components within the shock that regulate oil flow and damping resistance) are individually matched to the riding requirements and kinematics designs of our bikes.

5 Frame sizes

Flexible Production

For this frame we offer 5 sizes from S to XXL, suitable for body heights of 1.55 and 2.10. A chart of body and frame sizes can be found in the Tech Sheets attachment to this model. Building a perfectly fitting frame means more than just scaling its initial shape. Here we take into account various factors in terms of body proportions and rider weights, for example adapted tube cross-sections, modified riding angles and low standover heights for S-sizes as well as frame reinforcements that take into account the heavier weight and greater body strength of XXL riders. For fine-tuning the geometry, saddle position, stem height, or handlebar width and angle can be adjusted.

Powder coating and anodizing

Extralove

In addition to the basic configuration, in which we offer the frame without color in brushed aluminum look as Factory Raw with black anodized, mounted milled parts, there is the option of individual color choice. In our in-house powder coating facility, we process over 50 colors, each of which can be applied in high-gloss or silk matte.

Slide AFE

148 x 12

The Slide AFE called dropouts of the EBOXX meet the Boost standard with a hub width of 148 mm and a 12 mm thru axle. This ensures a particularly stable rear wheel and a higher torsional stiffness in the rear end and thus for a direct, loss-free power delivery and a precise, on-track riding performance. A Slide AFE is mounted in horizontal grooves and fixed in position by an adjustment bolt to match the specified chainstay length of the bike.

7020 Aluminum

All of NICOLAI frames are made of 7020-T6 aircraft aluminum and we are convinced that this alloy is the superior material for the construction of mountain bikes. Compared to the 6061-T6 (AlMg1SiCu) alloy normally used in bicycle construction, 7020-T6 (AlZn4.5Mg1) has about 30% higher tensile strength and about 20% higher elastic limit. And where carbon frames can spontaneously break and collapse in the event of an overload, NICOLAI bikes are calculated and designed to deform in a defined area of the frame in the event of an overload, significantly reducing the risk of serious crashes and injuries. A NICOLAI aluminum frame is designed to withstand many years even under tough competition conditions.

Topology optimisation

When designing turned and milled parts, we use FEM software (Finite Element Method), which allows us to simulate the loads that will occur in later use in order to determine the optimum shape (topology) of these components. Critical structural areas become visible this way and can be strengthened by adding material, whereas material can be saved at less stressed areas. This way we can produce highly complex parts and assemblies for our frames that combine maximum durability with minimum weight.

NICOLAI Welding

Made in Germany

We weld our frames manually using the TIG process. Our welders are specially trained and with many years of experience. For each model and frame size, a precise welding fixture is built, called a frame gauge. Here, the CNC-cut tube sets with all turned and milled parts of a frame that are to be welded are precisely put together and fastened. The frame parts are first tack-welded at exactly specified points and in a defined sequence and then, in order to minimize distortion and stresses, welded in several runs.

Warranty and spare parts supply

We provide a 5-year warranty on all frame models against breakage and material failure, even in racing use or when jumping. The prerequisite is that the respective models are used within the scope of their designated purpose and have been equipped only with the components for which there is an approval. In addition, we guarantee a spare parts supply for all models over a period of at least 10 years. Since we manufacture all parts of our frames in-house and on our own machines, it is even possible to reproduce spare parts beyond the 10-year period in some cases.

BIKEBOX

We have developed an elaborate reusable bike box for our mail-order shipping. In it, the new NICOLAI bike arrives protected in a wooden frame and guaranteed safe at the customer and is ready for use after a few simple steps. The same box is reused when the bike is returned to us for repair or service. All shipping protections of the bike box such as pads, lashing straps, brackets and screw connections are also reusable.