NUCLEON 16 UDH

one machine to cover all your needs for gravity, shred and speed

The Nucleon 16 UDH is the perfect machine for you if your idea of mountain biking is all about fast descents, technical trails and adrenaline-pumping action - or in other words: Enduro in all its glory. Available as a 29er or Mullet and with 165 or 175 mm rear travel, the Nucleon 16 features the most capable suspension design we have engineered to date. Its high-pivot technology offers superior performance on fast, technical descents, as the rear wheel follows the direction of the impact. At the same time, we were able to implement an ideal anti-squat behavior, so there is no sacrifice when accelerating and climbing. The Nucleon 16 UDH is optimized for the new derailleur generation of SRAM and equipped with a UDH mount for the particularly robust and precise SRAM AXS transmission derailleurs.

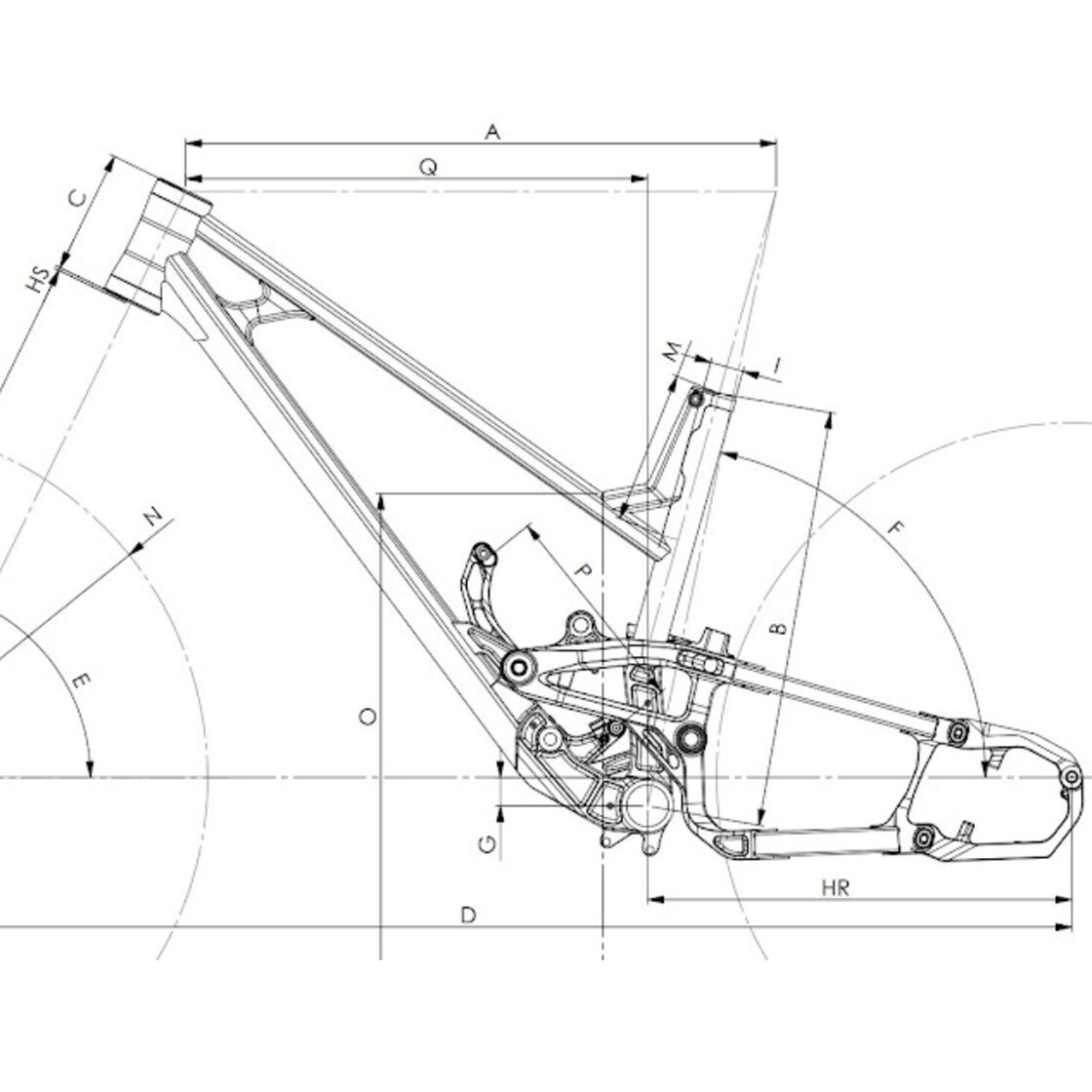

The Nucleon 16 geometry is based on our Geolution concept: a long reach, 490 mm in size M, combined with a 78.3 ° steep seat angle provides a sporty, central riding position and an optimal load distribution between front and rear wheel. The chainstay length grows with the different frame sizes and thus ensures a good balance. The head angle of 64° is slightly more moderate than on the extremely flat race enduros of the NICOLAI G series. This allows for more agile handling without significantly compromising running stability and high-speed behavior. The low top tube provides plenty of clearance with a standover height of 668 mm and encourages an all-action riding style. Whether enduro, all-rounder or freerider depends finally on you, the riders. With the Nucleon you get a powerful platform that meets all your needs for gravity, speed and action, but also performs well on epic adventures and big tours.

High Pivot

Performance gravity suspension with high swingarm pivot point

High pivot rear ends, where the swingarm pivot point is located well above the front chainring, have a decisive advantage over suspension systems with a low swingarm pivot point, usually at the level of the top edge of the chainring. When it comes to downhill and high speed, rough rides over obstacle-laden trails, high pivot bikes are significantly and measurably faster than low pivot bikes. This is due to the fact that the rear wheel, when hitting an obstacle, does not only bounce upwards as usual but also moves backwards at the same time according to a specific axle path. It thus follows the impact angle of a rock or a thick root much better. The rear wheel strikes less heavily against the obstacle. It does not hook up. So a high-pivot bike is less likely to be slowed down by rough bumps.

UDH Standard

Mounting standard for SRAM T-Type rear derailleurs at the thru axle mount

At the UDH standard, a SRAM AXS Transmission rear derailleur is attached directly to the thru axle of the frame rear. These rear derailleurs are designed significantly more stable than regular derailleurs and thus better protected against bending and ripping off. Their higher torsional stiffness also ensures higher shifting precision. SRAM AXS Transmission rear derailleurs are operated electronically and wireless and are optimized for shifting under maximum load. To minimize the effect of significant chain elongation that occurs with a high-pivot design, the Nucleon 16 UDH uses a lower guide pulley on the front chainring in addition to the upper idler. Thus, the returning chain is guided towards the swingarm pivot point, which reduces the elongation during compression. At the same time, this reduces chain slap and effectively prevents the chain from running off. Through the use of the lower guide pulley, the travel of the chain tensioner is within the technical limits that SRAM specifies for its Transmission derailleurs, even when the rear is fully compressed and in any gear.

Anti-Squat Design

Rear suspension design with optimized drive properties

With the Nucleon 16 we have realized an anti-squat characteristic with a maximum of 155% in the largest and 105% in the smallest gear, at a sag of 40mm. Compared to other high-performance enduro bikes, this means a particularly narrow spread of the anti-squat effect across the entire range of gears. A higher Anti-Squat value in medium to long gears is advantageous, since riding at high speeds is usually done standing up, with a rider applying significantly stronger load changes when pedaling. In small gears, on the other hand, the rider is usually seated and the load changes are correspondingly lower, but pedaling is most frequent in this gear ratio range. A lower but still effective anti-squat effect, as achieved by the kinematics of the Nucleon 16, is therefore optimal here.

Geolution

Our exclusive Enduro competition geometry

Geolution is a unique geometry concept based on the idea that a longer wheelbase, flatter steering angle and steeper seat angle make the bike faster, smoother, easier to climb and also safer. Climbing performance is improved because the steep seat angle and long front end put the rider in a position that prevents the front wheel from rising on steep climbs. The long wheelbase and a flat steering angle, on the other hand, allow high downhill and cornering speeds and prevent the feeling of going over the handlebars on steep downhill sections. The central seating position and the central center of gravity also provide an optimal load distribution between front wheel and rear wheel, which improves control in dynamic riding situations. This improves control in dynamic riding situations and the handling of the bike overall.

Topology optimization

Computer-aided design to optimize durability, function and weight

In the design of turned and milled parts, we use FEM software (Finite Element Method) to simulate the loads that will occur in later use in order to determine the optimum shape (topology) of these components. Critical areas of the design become visible in this way and can be strengthened by adding material, while material can be saved at less stressed points. In this way, highly complex parts and assemblies can be manufactured that combine maximum durability with minimum weight.

HMT

Hollow Milled Technology, load and weight optimized hollow milled volume components

Hollow Milled Technology is a design and manufacturing process that maximizes material and weight savings without weakening the structure when building highly stressed volume components such as the bottom bracket base of the new Nucleon 16. For this purpose, the stress zones in the material are determined by computer simulation during the design phase. Highly stressed areas can thus be strengthened, while material can be saved in areas subject to low stress. This method is called topology optimization. The use of state-of-the-art 5-axis milling machines allows us to manufacture highly complex, hollow-milled frame components from a single piece and to transfer the optimized design with the highest attention to detail.

Insert Bearings

four-fold sealed full-ball groove and angular contact ball bearings

The rear end of a full-suspension bike is subjected to high dynamic loads during riding. The focus here is on the bearing points where the forces are transmitted between the components. The full-ball, double-sealed bearings installed on our frames are made by the ENDURO brand. They not only have top marks for power transmission, but also a particularly low breakaway torque, which ensures sensitive, smooth suspension response. At the same time, they offer the best possible sealing against dirt and moisture for a long service life and long maintenance intervals.

Shocks

Shock technology with individually optimized setups

In order to achieve the maximum potential of a suspension system, the choice of the right rear shock is of decisive importance. We therefore offer for the Nucleon 16 a range of capable shocks of different price and performance classes. But whether you choose an affordable Marzocchi Bomber or a high-end EXT Storia, all available shocks have been tested by us with the Nucleon 16 and will deliver you all the benefits of its superior suspension design. Every shock we offer has optimized shim stacks (elements within the shock that regulate oil flow and resistance) that are tuned to the Nucleon 16's requirement profile and suspension characteristics.

5 frame sizes

Adaptive geometry and load-dependent modification

This NICOLAI model is offered in 5 frame sizes, allowing riders with body sizes from 1.64 to 2.10 meters to find their perfect fit. You can find a chart of body and frame sizes in the tech sheets below. Building a perfectly fitting frame means much more than just scaling its basic shape. We take various factors into account here with regard to body proportions and weights. For example adapted tube cross-sections, modified riding angles and particularly low entry and projection heights for S sizes or frame reinforcements that take into account the high weight and greater body strength of XXL frame riders. Saddle position, stem height, length and angle, and handlebar width and height serve to fine-tune the geometry.

7020 Aluminium

Sustainable and enduring

All our frames are manufactured from 7020-T6 aircraft grade aluminum, because we are convinced that this alloy is the superior material in the construction of mountain bikes. Compared to the 6061-T6 (AlMg1SiCu) alloy commonly used in bicycle construction, 7020-T6 (AlZn4.5Mg1) has about 30% higher tensile strength and about 20% higher elastic limit. The widespread use of 6061-T6 aluminum in frame construction is due in part to the fact that it can be processed at lower tooling costs and frames can be straightened after welding with less technical effort. Our frames are engineered and designed so that when overloaded, deformation occurs in a defined area of the frame rather than breakage, significantly reducing the risk of serious accidents and injuries. A NICOLAI aluminum frame is designed to withstand many years even under tough competition conditions.

NICOLAI Welding Technology

Craftsmanship and engineering in perfection

We weld our frames by hand using the TIG process. Our welders are specially trained for this and have many years of experience. For each model and frame size, a precise welding fixture is built, called a frame jig. In it, the CNC-cut tube sets are precisely assembled and fixated with all turned and milled parts of a frame that are to be welded. The frame components are first tacked with single spot welds at precisely specified points in a defined sequence and then, to minimize distortion and stresses, welded in several passes. Our characteristic, evenly flat-shingled NICOLAI welds are created by a very slow welding speed. This causes deep fusion of the material and large-area distribution of the loads and forces occurring in the frame.

Extra Love

powder coating and anodizing colors, decals, customizing, individualization

Thanks to a wide range of colors, every NICOLAI frame can be customized as desired. In our factory's powder coating facility, we process more than 50 colors, each of which can be applied in a high-gloss or satin finish. A separate color is possible for each welded frame component. Frames and frame components can also be anodized as an option, with a choice of black, bronze or titanium. An extended range of anodized colors is available for turned or milled applications such as bell cranks, bearing caps or cable clips, allowing color matching with common components, for example. We also offers an uncoated aluminum finish as "factory raw". If you then add the range of decals colors, the number of design options is almost limitless and a unique, personalized custom bike is guaranteed.

Bottle cage

mounting option for water bottles and accessories

Even though many of you use hydration backpacks or hip packs, very few want to go without the option of a bottle cage in the front triangle of the frame. For a clean look here ensure the magnetic FIDLOCK holder, which we offer together with a 0.6 L twist bottle. The FIDLOCK holder allows intuitive release and engagement of the water bottle in both directions while riding and keeps it securely in the frame even on the roughest trails. For further mounting options, for example to attach toolboxes, the plastic frame clamps from the NICOLAI accessories range are ideal. For the bottle cage threads in the frame we use aluminum rivet nuts. If, contrary to expectations, a thread should ever tear out or overtighten, it can be replaced with little effort.

Warranty and spare parts supply

NICOLAI grants a 5-year warranty on all frame models against breakage and material failure, even in racing use or when jumping. The premise is that the respective models are used within the scope of their designated purpose and are equipped only with the components for which there is an approval. In addition, the manufacturer guarantees a spare parts supply for all models for a period of at least 10 years. Since NICOLAI manufactures all components of its frames itself and on its own machines, in individual cases a subsequent production of spare parts is even possible beyond the period of 10 years.

Bike Box

We have developed an elaborate reusable bike box for our mail-order shipping. In it, the new NICOLAI bike arrives protected in a wooden frame and guaranteed safe at the customer and is ready for use after a few simple steps. The same box is reused when the bike is returned to us for repair or service. All shipping protections of the bike box such as pads, lashing straps, brackets and screw connections are also reusable.